Production effectivity for all your plants calculated immediately

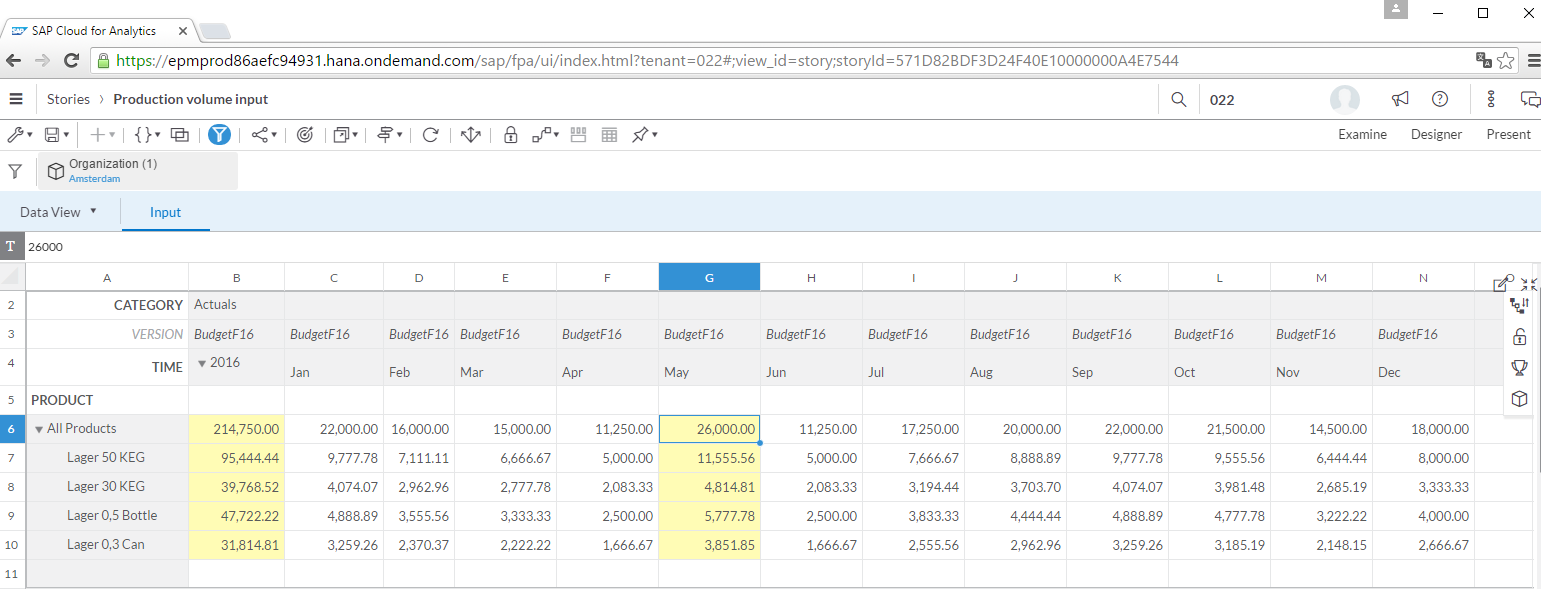

Production benchmarking and simulation is using SAP Cloud for Analytics platform to deliver you production calculations in very new and extremely flexible way. The solution is able to automatically load all your production portfolio including BoM for all sub-products. Changes can be simulated for BoM change, material substitution, supplier substitution with direct result calculation in technical and financial measures.

- Compare your production effectivity through product groups between countries.

- Find out exactly why your production in a given country costs less/more than average.

- Choose the best way of savings you have found by this comparison.

- Approve and accelerate appropriate changes on-the-fly.

What is the difference?

Bill of Material simulations – Bill of Materials (BoM) can be loaded directly from SAP PP or other production system. BoM can be updated, changed, simulated and recalculated without the need to touch the real production system. Multiple scenarios can be analyzed and thus optimal solution can be selected. The final approved BoM can be loaded back to SAP PP. Same changes can apply to multiple BoM or multiple sub-product levels.

Material changes – Raw materials and material consumption can be changed and simulated. Typically every change in basic material has vast impact on full production process. These changes can now be simulated on-the-fly through all products in production portfolio. This can be used to answer questions such as: „What would we gain from switching to new material supplier at group level?“

Automated benchmarking – Solution automatically calculates and compares production effectivity for all connected plants. It can identify and monitor the areas in which the given plant is particularly efficient and also point out the inefficiencies and possible changes. Automated benchmarking is also used by our customers to identify product recipes, which are not matching given product segments. (e.g. luxury packaging material with economy product…)

Automated savings identification – By comparison of benchmarks between production plants optimal alternative is found and possible savings are proposed. Savings could be found in production processes, material consumptions, indirect cost usage and many other areas.

Quality Excellence – Solution logic has been used by SABMiller Europe (15 breweries, 8 countries) this project has delivered significant production savings and has been awarded with SAP Gold Quality Award for EMEA region.

Powered by HANA Cloud Platform – full solution is using HANA database for cloud applications. This in-memory database is fully optimized for running extremely complex calculations such as product material breakdown and product portfolio simulation in matter of seconds.

Cloud enabled – full functionality is delivered as a service in highly secured SAP cloud platform. This means no extra cost is needed for hardware, IT staff and maintenance. Solution is highly scalable and can support hundreds of production plants and thousands of users working together on the same model.

SAP BO Cloud Production Benchmarking and Simulation.pdf